Shengtu Machinery, aslo known as Guangdong Shengtu Intelligent Equipment Co.,Ltd has been the leading manufacturer of the post-press and packaging machinery since its establishment in 1998, over the years ST has been specializing in case making machine, case lining machine, board slitting machine, hot stamping machine..etc, which are widely application in the hardcover book, stationery, photo album, packaging box industry..etc and have exported our machineries to more than 80 countries worldwide. In recent years, with the increasing demands of the collapsible boxes, most of the packaging box making customers require the automatic machinery to finish the process, thus making the whole process more efficient and saving the production cost. Therefore it is quite common to see the automatic collapsible box making machines in the market now. But what advantages of the latetst ST030 High Speed Collapsible Box Side Wing Making Machine has and how it is applicable in making the collapsible boxes?A. Applicable for various kinds of the collaspible box side wings making:

a)1 piece of normal board

b)3 pieces of board side wings(triangle boards 350gsm)

c)5 pieces of board side wings (triangle boards 350gsm)

d)5 pieces of board side wings with the connected triangle boards

e)5 pieces of board side wings with the different shape triangle boards

B. The max side wing size and the fastest collapsible box side wing making machine in the market: The maxi side wing size is 800x180mm and the stable production speed can be 1800pcs/h

C. Position device±0.25mm: photoelectric detection、servo rectification positioning as well as the visual positioning system(Optional)

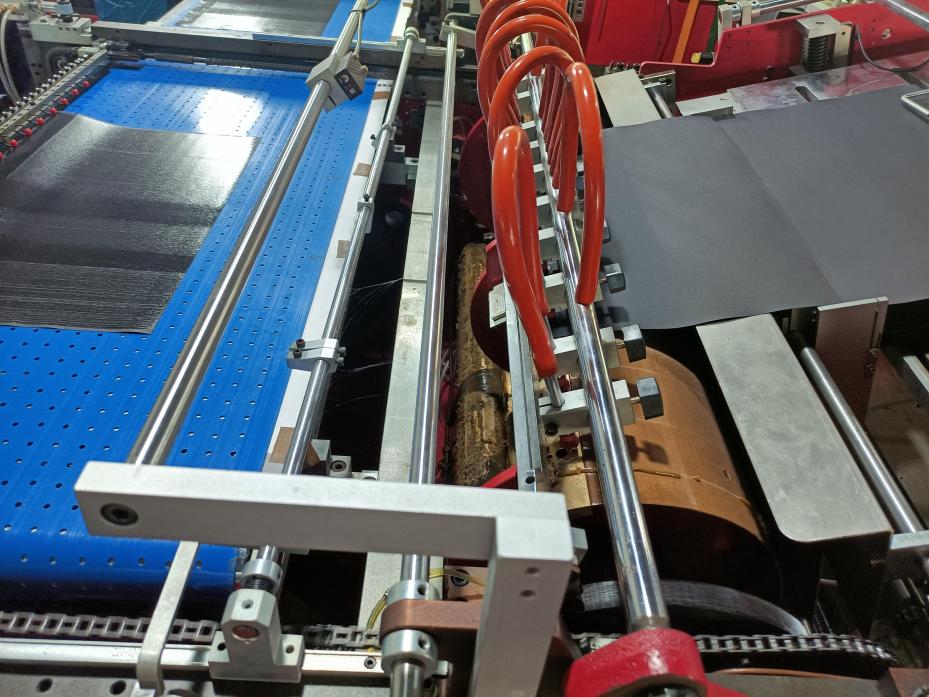

D. Side wing board feeding device: 4 separate delivering module to make sure the stability of the thin 300gsm side boards..etc

E. Cover feeding device: adopting the advantages of ST036 series of case making machine and applicable for the different thickness of the meterials from 80-270gsm. More importantly, cover with Spot UV, emboss, deboss, stamping process..etc can glue thinnest and evenly

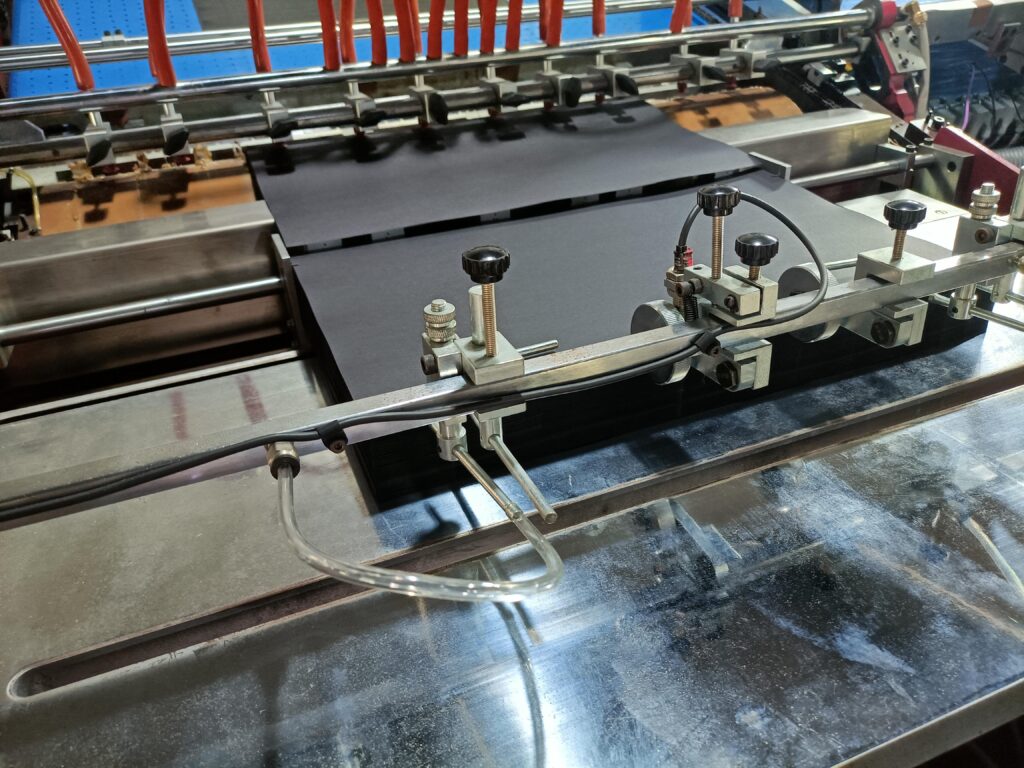

F. Cover gluing device: adopting the advantages of ST036 series of case making machine and applicable for the different thickness of the meterials from 80-270gsm. More importantly, cover with Spot UV, emboss, deboss, stamping process..etc can glue thinnest and evenly

G. Cover folding device: adopting the brushes for folding the edges without any air bubbles and empty edges..etc, applicable for 80gsm cover folding in high quality..

H. Pressing device: adopting the pressing roller for pressing 3 times tighly and saving the next production process

From the above we can see that for making the collapsible boxes not only for the long runs but also for the short runs job, ST030 High Speed Collapsible Box Side Wing Making Machin would be the best choice for the investment.