During the exhibition, SHENGTU has displayed their latest models and technologies in the application of the photobook、packaging box, screen printing industry..etc to meet the customers’ requirements, which has received the great popularity and good response..etc.

Digital photobook application:

ST060D Digital Hardcover Machinehas been displayed to make PU round corner, which is widely applicable for hardcover book, stationery, photo album industry..etc and also the only case maker in China to mee the traditional as well as the digital areas.

1、1-5 minutes making-ready time can save the preparation time and improve the production efficiency, which can slove the short runs job prdocution problems.

2、Data storage function can make the adjustment more easy and simple especially for the repated jobs.

3、ST060D can be connected with the company internal system such as ERP and MAS..etc, which can monitor the production data and production status, thus achiving the intelligent production.

ST060D can also be applicable for the traditional hardcover book industry..etc

1、The production speed can be 3000pcs/h, thus it can meet the requirements of the long-run jobs and improve the production efficiency.

2、Round corner production, it is suitable for both digital and traditional industry, Regarding the round corner making on ST060D, it can be divided into 2 types: The one is the common corner cutting to fold the round corner, which can save the die-cutting process and is more efficient for round corner making. The other one is die-cutting the paper corners, especially for the PU round corner, which can improve the competitive edges for the various kinds of material application.

ST015D Photobook casing in machineis used in the digital photo album industry/area. As we all know, the digital allbum is for the short run and fast run jobs as well as requiring the fast delivery time, however our ST015D photobook casing in machine has well solved these problems.

1、make-ready time only requiring 1-2 minutes.

2、Data storage function can make the adjustment more easy and simple especially for the repated jobs/orders.

3、ST015D can be connected with the company internal system such as ERP and MAS..etc, which can monitor the production data and production status, thus achiving the intelligent production.

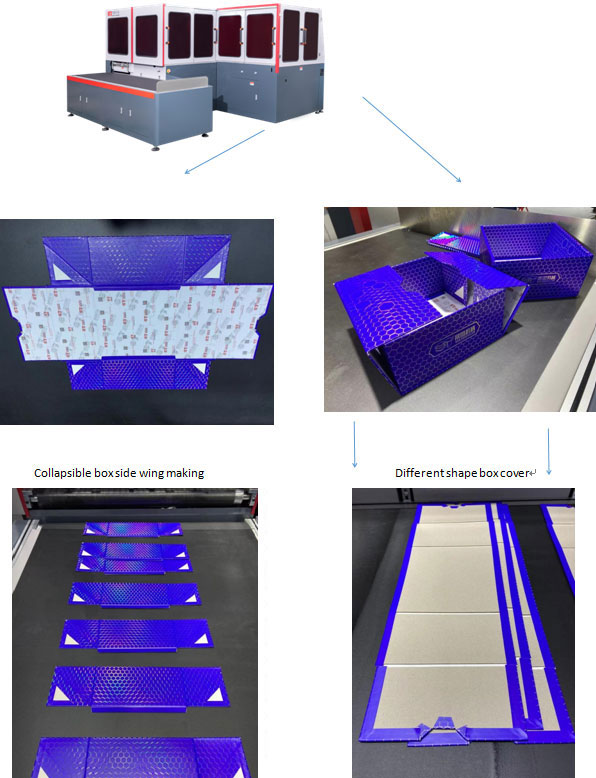

Lurxy packaging box application:

ST036XL Automatic Hardcove Machine has been displayed to make the side wings and the diffrent shape hard case for the collapsible box solution, which is widely used in the cigarette box, liquor box, cosmetic box, electronic box..etc, the max case size is 850x450mm, the mini case size is 100x45mm, the production speed can be 1800-1500pcs/h, thus it is the most wide application and multi-functional case making machine in the market.

A)For making the different sizes of the side wings, there will be no need to make the special die, thus saving the production costs.

B)By adopting the integrated board feeding device, it can be flexibly applicable for making the outside hard case as well as the side wings, which can save the make-ready time greatly and imrprove the production efficiency.

C)Newly-developed triangle board feeding device can make the 300 gsm thin board run more stably, thus ensuring the stable capacity.

D) The integrated folding device adopts the brush foding system, which can fully-fold the side wings more tightly and applicable for more materials. Meanwhile, the adjustment is more easier and simple.

Screen press with cold foil&cast cure solution:

ST1050AH Automatic Stop Cylinder Screen Press has absorbed the latest domestic and international technology and design on the basis of our many years’ rich experiencce on manufacturing the cylinder screen press, after innovation it has been the most popular and wide applicable model. The fast production speed can be up to 4000pcs/h, meanwhile the machine has adopted the non-stop feeder and non-stop collection technology, thus improving the printing efficiency for more than 30%. To ensure the reliability of the function of its unique design,the key parts of the machine are processed by imported procession machine tools and the key components are imported directly from abroad.It is really the ideal equipment for offeringthe better and faster as well as the high quality printingfor those industriessuch as packaging and advertisement printing industry (printing on coated paper,paper board,cardboard, stick paper, polyethylene, polyester, polypropylene and spot varnishing with UV ink), transfer printing industry (printing labels of pottery, glass, lottery ticket and enamel ) and electronic printing industry (printing soft circuit board and flexible film button)..etc.